In 2020, the Clean Energy Smart Manufacturing Innovation Institute (CESMII) announced more than $6 million in funding for eight projects to improve energy-intensive manufacturing processes and to strengthen the U.S. manufacturing sector.

ITAMCO, West Virginia University, and Clemson University were chosen to develop hybrid modeling for energy efficient grinding processes for gear manufacturing.

PROBLEM TO BE SOLVED:

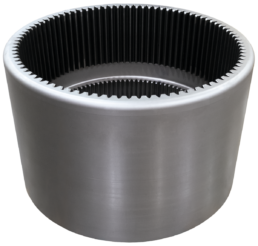

Grinding is of the upmost importance in industry, and is essential for creating parts from hard and brittle materials. However, out of all machining processes, it is the one with the highest energy consumption. (SEC) The total grinding time for ITAMCO’s Ring Gear (Pictured below) accumulates 11 hours of energy, and is responsible for 33% of the total manufacturing cost of the gear.

PROJECT OBJECTIVE:

The principal goal is to reduce the extremely high energy consumption of grinding processes for gear manufacturing by at least 15% through hybrid modeling of the grinding system holistically.

TECHNICAL APPROACH:

To achieve this goal, we will develop novel hybrid modeling methods that combine multi-physics equation-based models with data-driven machine learning models. The hybrid model input includes both machine tool parameters and sensor data as well as data from ERP and tool management systems. The hybrid model’s output provides grinding process parameters (wheel speed, depth of cut, infeed duration) as well as grinding tool reconditioning schedule and parameters (dressing and sharpening) that reduce the overall grinding system’s SEC. The model will be prototypically implemented in the industrial testbed will be located on-premise at ITAMCO, a leading US gear manufacturer and SME.

POTENTIAL IMPACT:

The US demand for gears is expected to grow by 6.4% to $40 billion in sales. Grinding will remain the core technology to produce large-scale, high-quality gear components. The novel, scalable, and generalizable hybrid modeling approach and its deployment in the CESMII SM platform environment will provide a blueprint for other use cases to reduce the energy consumption of the US grinding industry.

ITAMCO’s Niles ZP40, which is the primary machine on which their Ring Gear is ground.

BENEFITS TO CESMII:

The project showcases rapid recovery of Smart Manufacturing adoption cost through energy savings and productivity increases in an industry with energy intensive processes. The project creates an opportunity to scale its impact for other interested CESMII members across industries (automotive, aerospace, medical, etc.) and applications (milling, turning, etc.) within the larger CESMII network.

IMPACT VS PERFORMANCE METRICS:

15% reduction in energy consumption & 3-7% increase in productivity lead to an estimated increased throughput of 28 additional units, and annual savings of ~$143,000 and ~1,000t CO2at ITAMCO alone.

Information from Dr. Thorsten Wuest, West Virginia University

ITAMCO

ITAMCO has been recognized as one of the premier advanced manufacturing and technology firms in the United States. We collaborates with like-minded professionals from the world’s most respected companies and universities across the globe to solve complex challenges and deliver innovative solutions.