ITAMCO Wins Contract with US Air Force to Develop 3D-Printed Runway Mat

Plymouth, Indiana. May 20, 2019. ITAMCO (Indiana Technology and Manufacturing Companies) is part of a team developing a new runway mat for the United States Air Force. Runway mats are a critical component of Expeditionary Airfields (EAFs).

EAFs are portable airfields that can be constructed, used, broken down after the completion of a mission, and moved to another site for re-use. These portable airfield mats must be easy to install and store, yet capable of withstanding the stresses of repeated take-offs and landings of aircraft and the impact from arresting hooks. The portable runway surface most used today is made with an aluminum plank matting called AM-2. AM-2 matting has served the United States military well since the Vietnam War, but the materials and technology in the ITAMCO-led research project will offer many benefits over AM-2 matting.

Project Objective

The objective of the research is to develop a robust sheet or roll technology that serves as an alternative to the Vietnam War-era AM-2 mat for temporary or expeditionary flight operations. Scott Hartford, Project Manager at ITAMCO is working on the project with Professor Pablo Zavattieri in the Lyles School of Civil Engineering at Purdue University. The proposed technology solution is comprised of an upper surface that mates with a lower surface and contains Phase Transforming Cellular Matrix (PXCM) geometry to mitigate anticipated loading and shear stresses.

What is PXCM? In the simplest terms, products made with PXCM geometry have the ability to change from one stable configuration to another stable configuration and back again. According to an article by Nadia Aljabi in the Journal of Purdue Undergraduate Research, the novelty and benefits of PXCM are that they can absorb important amounts of energy and yet be reusable since the phase transformation is entirely reversible without inducing permanent deformation into the base material. This means the new runway mat can “heal” itself, resulting in a much longer lifespan than a runway made with AM-2 matting.

Additional benefits of the new runway material include:

- The PXCM solution is targeted to weigh 3.5 lb. per sq. ft. or less. It can be laid by hand over a level surface of the appropriate density.

- Debris on the runway will not hamper the runway’s performance.

It will support flight operations of 5,000 landing and takeoff cycles over 60 days.

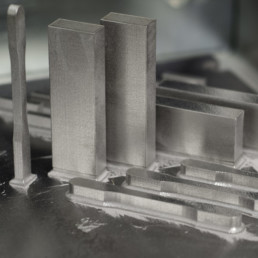

The 3D Printing of the Runway Materials

The construction of the proposed runway mat is as innovative as its use of PXCM geometry—the prototypes of the mat will be made on ITAMCO’s EOS M290 additive manufacturing printer. The 3D printing method will be a collaboration between an innovative metal powder called StainlessSteel 316L VPro and the unique additive manufacturing capabilities of the EOS M290 printer. This union between product and printer will reduce production time by 70 percent and cost by up to 50 percent.

“EOS StainlessSteel 316L VPro is a highly productive material that was born from our collaborate development effort with GKN. Applications using 316L VPro, combined with highly proven EOS metal 3D printing technologies, result in accelerated production with lower production costs,” said Patrick Boyd, Marketing Director, EOS North America. “We’re excited that ITAMCO has partnered with EOS in ITAMCO’s endeavors to create forward-thinking solutions. They are not afraid to engineer then employ extraordinary solutions where no solution previously existed.” Pushing boundaries with innovative materials and state-of-the-art printers does not guarantee build success; however, so the ITAMCO team is using Sunata™ from Atlas 3D to optimally orient and support the PXCM geometry. “The additive markets continue to evolve with new materials and unique geometries like PXCM on a near daily basis,” said Chad Barden, CEO of Atlas 3D. “If not managed properly, these new variables can lead to scrap, rework, and loss of time to market. Sunata will ensure build success and is an integral part of this project.”

The Project Partners –

ITAMCO

Since 1955, ITAMCO has provided open gearing and precision machining services to heavy-duty industries including Mining, Off-Highway Vehicles, Marine, and Aviation. In addition to the company’s offerings in traditional manufacturing, the technology team at ITAMCO has released over 65 applications for mobile devices; designed and markets iBlue, the first industrial Bluetooth transmitter; developed an award-winning Google Glass application; and launched their successful “Strategic Technology Initiative for Additive Manufacturing” in 2015. The company continues to explore alternatives to traditional processes: ITAMCO has received grants to develop PXCM-based capabilities for both the United States Army and Air Force as well as solutions for the United States Army and Navy. Learn more about ITAMCO at www.itamco.com or call (574) 936-2112.

Pablo Zavattieri with the Lyles School of Civil Engineering at Purdue University

Pablo Zavattieri is an associate professor at Purdue University. His contributions to industry and academia focus on the boundary between solid mechanics and materials engineering. The Lyles School of Civil Engineering, ranked among the top in the nation, generates solutions to critical global problems.

EOS

EOS is a leading technology supplier in the field of industrial 3D printing of metals and polymers. Formed in 1989, the independent company is pioneer and innovator for comprehensive solutions in additive manufacturing. Its product portfolio of EOS systems, materials, and process parameters gives customers crucial competitive advantages in product quality and the long-term economic sustainability of manufacturing processes. Furthermore, customers receive deep technical expertise in global service, applications engineering and consultancy.

Atlas 3D

Developed in 2015, Sunata™ by Atlas 3D is a cloud-based, ITAR-compliant software developed to support Direct Metal Laser Sintering (DMLS) Printers. Known as the metal additive “Easy Button,” it chooses the optimal orientation and automatically generates the necessary support structures to ensure a successful build. Currently, Sunata is used at Fortune 500 companies, the United States Department of Defense, cutting-edge manufacturers, medical devices companies, and many other.

Easing Additive Manufacturing Design

The orientation of a part on the metal Additive Manufacturing (AM) build plate is one of the most important aspects of AM builds.

Having the proper orientation optimizes support-structures, minimizes thermal distortion, can reduce finishing time, and produces an optimal part. 3D Metal Printing Magazine released a blog post highlighted part orientation in AM. Optimizing the orientation on the build plate can be difficult, and often there is no “right” orientation, only an optimized solution with tradeoffs made along the way.

ITAMCO’s subsidiary Atlas 3D has developed a solution. Their could-based software, Sunata, automatically chooses the best orientation for a part and generates the necessary support structures for a successful AM build. Read the complete article to learn more about how Sunata is revolutionizing the metal AM design process.

Ramping Up Additive Manufacturing With New EOS Printer

ITAMCO (Indiana Technology and Manufacturing Companies) is delivering components, made with its new EOS M 290 additive manufacturing printer, to the medical device industry. The EOS printer was delivered in June 2017, and ITAMCO was shipping components to a medical device supplier in August.

The fast ramp up is partially due to the experience the ITAMCO team gained while contributing to the development of additive manufacturing software. They were part of a consortium of manufacturers and universities that collaborated to develop the program through a multi-million dollar manufacturing initiative called “America Makes.” The software, named Atlas 3D, is now marketed through a division of ITAMCO.

ITAMCO, EOS Partnership

Another reason for ITAMCO’s efficient entry into additive manufacturing was EOS. “The EOS printer is the right tool for our complex components made with DMLS (Direct Metal Laser Sintering) and the EOS team trained our staff and got us up and running quickly,” said Joel Neidig, director of Research and Development for ITAMCO. “The printer works seamlessly with Atlas 3D too.”

In addition, the technology team at ITAMCO built a good working relationship with the EOS sales and support team. Jon Walker, area sales manager with EOS North America, said, “ITAMCO is an ideal partner for EOS because three generations of ITAMCO leaders have supplied traditional subtractive manufactured parts to some of the best known organizations in the world. ITAMCO’s investment in additive manufacturing validates the 3D printing market, especially in highly regulated industries where testing and validation of components or devices is critical. We’re thrilled that they have invested in an EOS M 290 3D printing platform, smartly positioning themselves to become an additive manufacturing leader in robust medical and industrial markets for the next three generations and beyond.”

Servicing Medical Device Industry

The medical device industry is a relatively new market for the company that has serviced heavy-duty industries for decades. “Additive manufacturing is allowing us to do things we’ve not done before, like producing the smaller, more intricate components for the medical device industry,” said Neidig.

Given ITAMCO’s capabilities and their close proximity to numerous medical implant manufacturers in Indiana, the entry into this industry is a logical move. “We’ve hired two people from medical device companies to work for us,” said Neidig. “We will continue to expand our presence in our current markets by offering additive manufacturing and the high-quality subtractive manufacturing that made us so successful.”

ITAMCO has been on track to include additive manufacturing in its offerings since the launch of the “Strategic Technology Initiative for Additive Manufacturing” in 2015. ITAMCO is using additive manufacturing to expand its market position in a global economy and to deliver real benefits to customers. Benefits include a faster turnaround, lighter yet stronger components, lower prices, design freedom, product customization, and reasonably priced small-batch production.

Secure Messaging App for the US Military

Indiana Technology and Manufacturing Companies (ITAMCO), an American technology company, announced that it received a Phase 1 grant from the Defense Advanced Research Projects Agency (DARPA).

ITAMCO will use the funds to create a more efficient, robust, and secure platform using Hyperledger for Department of Defense communications. According to ITAMCO’s announcement, the project will combine new technology with the company’s existing Crypto-Chat application – a messaging app that uses 256-bit AES encryption protocols.

ITAMCO Visits the White House

Joel Neidig traveled to the White House to talk about the success his company and other manufacturers have made and the future of manufacturing in the United States.

Joel’s grandfather, Noble Neidig, founded ITAMCO in Plymouth in 1955. Since then, the family-owned business has made gears for many heavy duty industries like mining, off-road highway vehicles, and aviation. Customers include Caterpillar, GE, NASA, and the Department of Defense.

“We continue to grow. We recently expanded some of our manufacturing capabilities into some new five access equipment in gear manufacturing.”

– Joel Neidig.

ITAMCO awarded one of the Top Supply Chain Innovators of 2016

At ITAMCO, each forklift is linked to the company's ERP system through its GPS and an application on a smart tablet mounted in the forklift.

“We developed the application because both of our facilities are rather large and forklift operators where always looking for forklifts to move their material but could never find one,” explains Joel Neidig, Director of Research and Development.

“Also, material would sit for hours at a machine, delaying the next operation. This application solved the problem by notifying a material handler as soon as the materials were ready to go to the next work area,”

Now, as soon as a machine operator scans the barcode on a pallet, signifying the completion of the product cycle at his machine, a forklift operator and forklift are on their way to the machine. Each forklift is linked to ITAMCO’s ERP system through its GPS and an application on a smart tablet mounted in the forklift.

This innovation approach earned ITAMCO a spot on Material Handing and Logistics’ list of Top Supply Chain Innovators of 2016. See the list here.

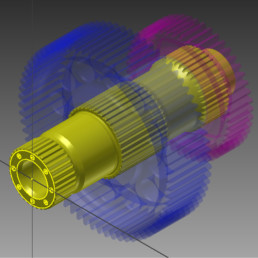

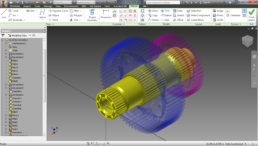

ITAMCO Named 2014 Autodesk Inventor of the Year

ITAMCO was featured in Fortune for ongoing development of wearable technology and finding innovative ways to incorporate it into manufacturing .

Members of the Autodesk Manufacturing community worldwide selected ITAMCO as the Autodesk Inventor of the Year for 2014.

Autodesk works to identify the most innovative customers from among hundreds of thousands of designers and engineers that create using Autodesk manufacturing tools.

Based in Plymouth, Indiana, ITAMCO delivers precision-machined components to original equipment manufacturers that serve a wide array of industries. Click here to learn more. ITAMCO leverages Autodesk Inventor 3D design software to better serve its customers.

“We are thrilled and honored to be recognized by the Autodesk Manufacturing community for this award. It was certainly a team effort!” said Joel Neidig, Technology Manager at ITAMCO.

For ITAMCO, the more precisely a gear is manufactured, the better it will perform, and using Inventor software for design and manufacturing processes makes it possible for the company to manufacture gears to incredibly precise sub-micron tolerances at .00004 inches.

ITAMCO featured in Fortune Magazine

ITAMCO was featured in Fortune for ongoing development of wearable technology and finding innovative ways to incorporate it into manufacturing .

ITAMCO developed technology that uses image-recognition software to help machinists and mechanics identify parts and tools as they examine them.

ITAMCO Named Autodesk Inventor of the Month

ITAMCO has been named the January Inventor of the Month for using Autodesk Digital Prototyping tools — including Autodesk Inventor 3D design software as part of Autodesk Product Design Suite, along with Autodesk Factory Design Suite — to better serve its customers

“The more precisely manufactured a gear is, the better it will perform,” said Joel Neidig, technology manager at ITAMCO. “Using Inventor software for our design and manufacturing processes makes it possible for us to manufacture gears to sub-micron tolerances, which is .00004 inches. That’s very precise.”

This level of precision satisfies even the most demanding customers – like NASA, which used some of ITAMCO’s gears on the mechanical arm that built the international space station. Or the Department of Defense, which uses ITAMCO’s gears on some of its land-based satellite systems.

TAMCO’s operations have also been significantly enhanced by Factory Design Suite, which allows users to digitally optimize a factory layout before it’s completed. This digital exploration came in handy when the company ordered a colossal piece of machinery that can produce gears up to 13 feet in diameter and that weigh as much as 80,000 pounds.

As ITAMCO has continued to expand, the company has used Factory Design Suite to lay out new cells and equipment and make sure it meets the 5S standards of organization and efficiency across the factory floor. It’s just one more way Autodesk digital prototyping software helps ITAMCO – and the diverse range of customers that depend on them – keep things moving, literally and figuratively.

ITAMCO Manufacturing Education School Service Center (IMESSC)

A Partnership between Plymouth Schools, ITAMCO and Ivy Tech will offer Precision Tool Manufacturing Training

High school students in Plymouth and the surrounding school corporation now have a higher education option. Ivy Tech Community College is offering dual credit precision tool manufacturing training courses to Plymouth High School. The courses will be offered in a newly renovated facility at PHS and be taught by an Ivy Tech instructor.

Jerry Hollenbaugh from the North Central Vocational Cooperative said his program serves 10 school corporations and the new CNC program at PHS has 13 students enrolled from three corporations, Plymouth, Culver and John Glenn. He commended Mark Neidig II from ITAMCO for taking the initiative to approach Plymouth’s Superintendent Dan Tyree with the request for a training opportunity for students and then having them step up to the plate and make it a partnership with financial support.

MT Connect: Two Shops Share Their Experience

For two shops in northern Indiana, using MTConnect for machine monitoring was just the start. Both shops are now ready to implement other promising applications.

Most manufacturing companies prefer to adopt new technology by starting small, accepting modest initial gains, and then adding more with expectations of big rewards later. MTConnect, it seems, follows a somewhat different path. Companies implementing this data standard are getting big results almost right away.

That’s because MTConnect enables them to unlock data from machine tools and other production equipment that reveals problems or bottlenecks that were difficult, if not impossible, to detect before. In many cases, fixing these problems can be relatively easy (for instance, immediately adjusting a production schedule or ordering timely maintenance). The results are better utilization of production equipment, more on-time deliveries, less guesswork about shop management and other benefits.