Built for Versatility

ITAMCO’s broad manufacturing capabilities allow us to support complex components from concept through completion. From precision gear manufacturing and additive processes to complete gearbox builds, we provide the flexibility and control required for demanding applications.

Explore our growing range of manufacturing capabilities.

Download our Capabilities

Fill out the form below to download ITAMCO's capabilities.

Precision Machining

Specializing in prototyping, serial production machining, and project management. ITAMCO’s versatility demands innovative manufacturing processes and advanced technology.

Precision Boring

Size Capability:

X = 120" or 3050mm

Y = 90" or 2280mm

Z = 96" or 2450mm

Vertical Machining

Size Capability:

X = 80" or 2050mm

Y = 50" or 1270mm

Z = 50" or 1270mm

Horizontal Machining

Size Capability:

X = 120" or 3050mm

Y = 90" or 2280mm

Z = 96" or 2450mm

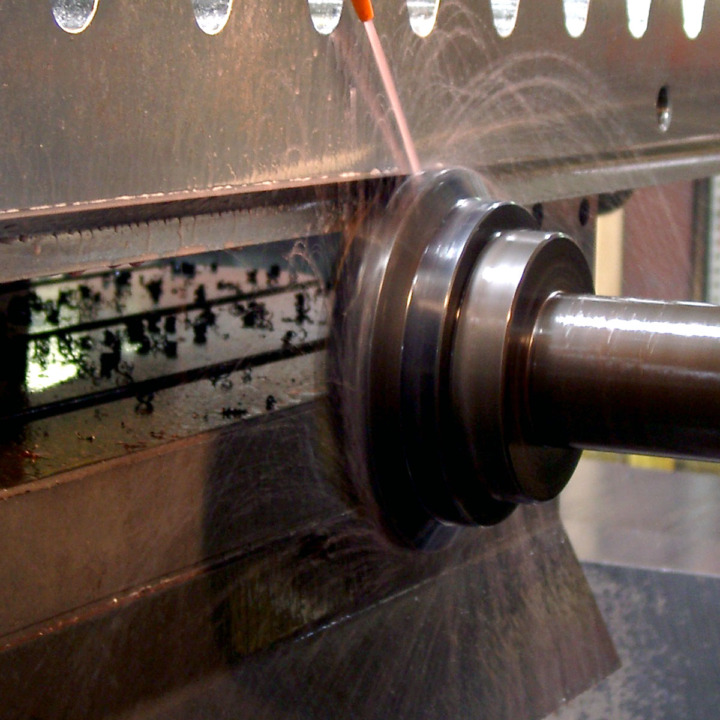

Turning

Size Capability:

D = 30" or 762mm

L = 84" or 2133mm

Vertical Turning

Size Capability:

D = 120" or 3000mm

L = 90" or 2300mm

O.D. Grinding

Size Capability:

D = 16″ or 406mm

L = 72″ or 1850mm

I.D. Grinding

Size Capability:

D = 24″ or 600mm

L = 18″ or 450mm

Coordinate Measuring

Size Capability:

X = 156″ or 4000mm

Y = 100″ or 2500mm

Z = 60″ or 1525mm

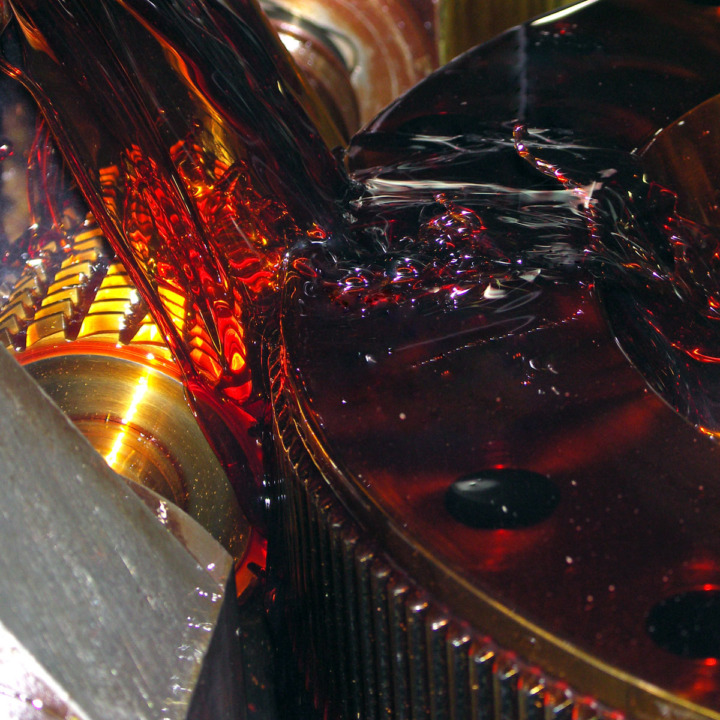

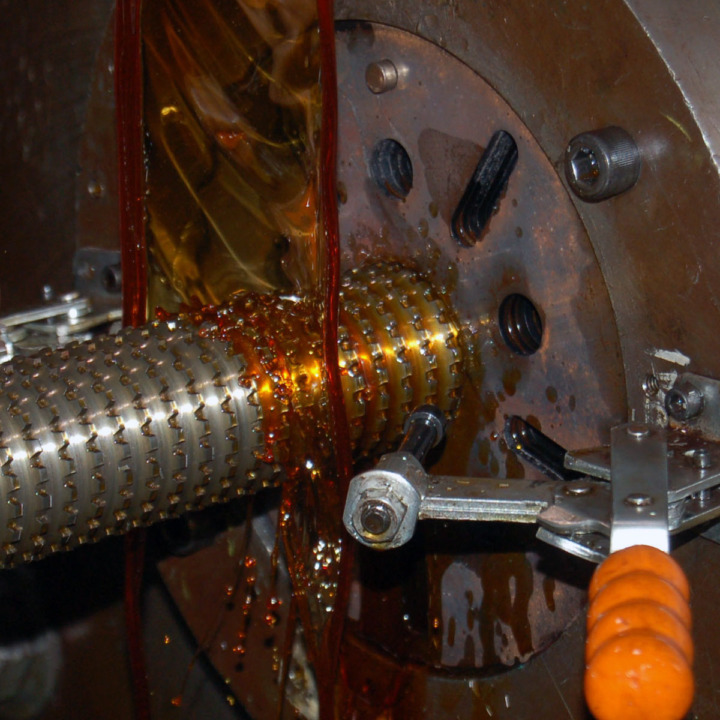

Open Gearing

ITAMCO is considered by many to be one of the most unique gear manufacturing companies in the world. Our capabilities range from large mining gears to high precision ground gears.

Gear Shaping

Size Capability:

D= 72" or 1850mm

L= 15" or 400mm

Gear Hobbing

Size Capability:

D= 78" or 2000mm

L= 48" or 1225mm

Gear Gashing

Size Capability:

D= 78" or 2000mm

L= 48" or 1225mm

Broaching

Size Capability:

Up to 50 ton

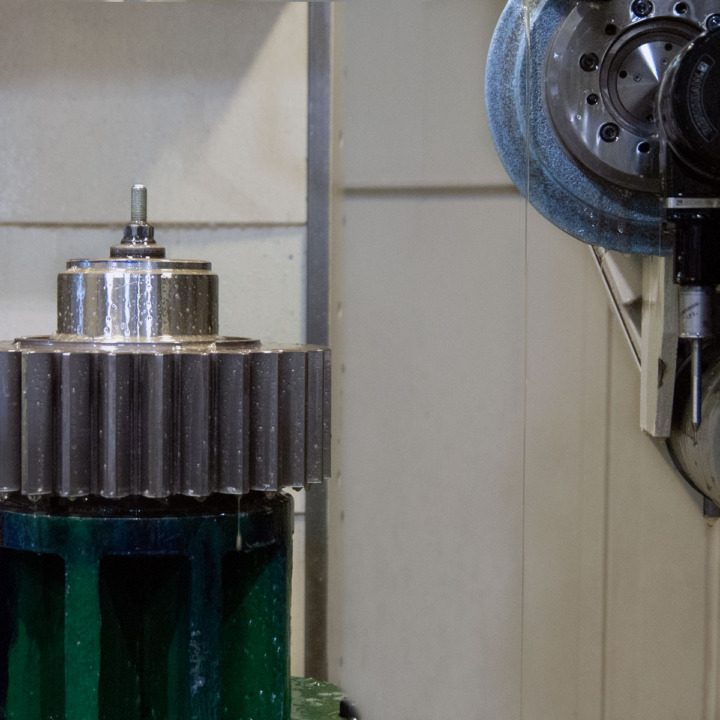

Gear Grinding

Size Capability:

D= 156" or 4000mm

L= 70" or 1750mm

Large Part and Gearbox Assembly

ITAMCO’s large-scale assembly facility is located in Argos, IN, conveniently located for easy rail or major OTR (over the road) transportation. This 385,000 sq.ft. facility is equipped with cranes up to 110 tons and expansive teardown, rebuild, and new gear drive manufacturing cells.

- 110 ton crane capacity

- 60 foot ceiling height in assembly hall

- Electric soft start for motors up to 6000 HP

- Gearbox spin test stands

- Temperature, noise, and vibration monitoring

- Electrical and lubrication systems assembly

- Gearbox tear down, kiss grinding, and rebuild services

- Custom and serial production volumes

385,000 sq. ft.

60 Foot High Bays

110 Ton Crane Capacity

Finishing and Non-Destructive Testing

ITAMCO offers extensive finishing and non-destructive testing capabilities to comply with your specifications.

Shot Peening

Size Capability:

20' x 20' Blast Grit Room

60" Diameter Shot Peening

Multi Specification Compliant

Part Cleaning

Featured Capability:

Ultra Sonic Cleaning

Large Conveyor and Vestibule Washers

Isotropic Surface Finishing

Featured Capability:

REM Process

Hardness Testing

Capability:

All Rockwell Scales

Leeb (portable)

Brinell

Non-Destructive Testing

Featured Capability:

Dye Penetrant

Magnetic Particle Inspection (MPI)

Ultrasonic Testing (UT)

Surface Temper (Nital Etch)

Surface Roughness Testing (Portable Profilometer)

Quality

ITAMCO has produced high-quality, precision-machined components for our customers since 1955. To maintain this standard of excellence, we have continually refined our quality systems to meet the demands of our clients.

ITAMCO’s quality systems are registered to the ISO 9001:2015 standard. Click here to view our certificate. Our quality control labs feature state-of-the-art Zeiss CMM’s with measuring envelopes of up to 160″. All CMM’s are equipped with state-of-the-art gear inspection capabilities. These machines allow us to gather and analyze quality data on large machined parts and geared or splined products.

We’ve also added several FaroArm-Platinum portable CMM’s to expand our inspection capabilities beyond the quality control lab. Our certified operators can now inspect or perform CAD-to-Part-analysis on parts anywhere the customer requires it while maintaining accuracy within +/- .0005″.

ITAMCO's Quality Policy:

To provide products and services that meet or exceed customer expectations and to achieve customer satisfaction by the continuous improvement of our Quality Management system.

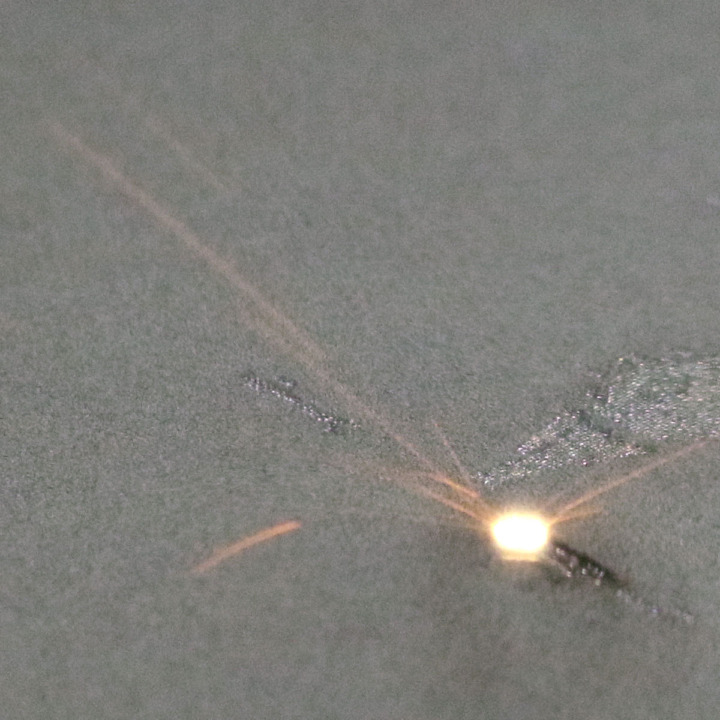

Additive Manufacturing

ITAMCO can handle your complete Additive Manufacturing part from start to finish.

Building Volume

250 mm x 250 mm x 325 mm

(9.85 x 9.85 x 12.8 in)

Laser Type

Yb-fiber laser; 400 W

Precision Optics

F-theta-lens; high-speed scanner

Scan Speed

up to 7.0 m/s (23 ft./sec)

Focus Diameter

100 μm (0.004 in)

Metal Options

TI164, 316L Stainless Steel, AISI10MG, Ferrium C64 Steel, 17-4PH Stainless Steel, INCONEL718, and more