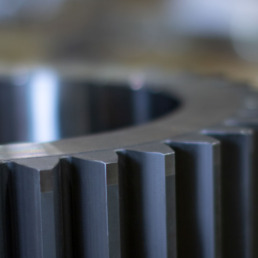

Revolutionizing Potash Mining: ITAMCO’s Advanced Gear Manufacturing Elevates Continuous Boring Miners

In the dynamic world of mining, efficiency and reliability are paramount, especially in industries like potash…

ITAMCO Revolutionizes Gear Manufacturing at THRIVE Energy Conference

The recent THRIVE Energy Conference served as a prime platform for ITAMCO (Indiana Technology and Manufacturing…

ITAMCO’s Next Generation Gear Manufacturing Revolutionizes Fracking Efficiency in the Oil Industry

In the ever-evolving landscape of industrial technology, efficiency is paramount. Enter ITAMCO (Indiana Technology and…

Joel Neidig Brings Expertise to MTConnect Board of Trustees: A Pioneer in Advancements

In a significant move that underscores the ongoing evolution of manufacturing technology, Joel Neidig, the visionary…

MxD Welcomes ITAMCO CEO to Board of Directors

December 13, 2023 (CHICAGO) — MxD today announced the addition of Gary L. Neidig, President and CEO of Indiana…

ITAMCO’s Joel Neidig to speak at the Motion + Power Expo

Save the Date!Join ITAMCO at the Motion + Power Technology Event this coming Tuesday, October 17th, at 10:30 a.m. for…

ITAMCO’s Joel Neidig to speak at Fabtech 2023

ITAMCO at Fabtech 2023We’re thrilled to announce that Joel Neidig will be speaking at Fabtech this year! Fabtech…

Making CNC Grinding More Energy Efficient

In 2020, the Clean Energy Smart Manufacturing Innovation Institute (CESMII) announced more than $6 million in funding…

ITAMCO Wins Small and Medium-sized Manufacturer of the Year

In an annual event to commemorate innovation in hardtech and manufacturing, ITAMCO has won the small and medium-sized…

Grant to Improve DoD Smart Tech

The Indiana Economic Development Corporation (IEDC) is awarding grants totaling $650,000 to three Hoosier companies to…

Winning Gold in the USAF’s Advanced Manufacturing Olympics

Blockchain startup SIMBA Chain, with help from the ITAMCO team, edge out Boeing and Stratasys for $100,000 first prize…

ITAMCO Developing Portable Runway Mat

ITAMCO is competing for a Phase II Small Business Innovation Research (SBIR) grant for additive manufactured portable…

Additive Manufacturing Virtual Summit

ITAMCO is excited to announce the third-annual Additive Manufacturing Summit on Tuesday, July 14 from 1-4 p.m. EST.…

Changes in Smart Manufacturing

West Virginia University and ITAMCO are advancing smart manufacturing with a $901,486 grant awarded by the United…

Leading Through Collaboration

Indiana Technology and Manufacturing Companies (ITAMCO) have long been recognized as premier advanced manufacturing and…